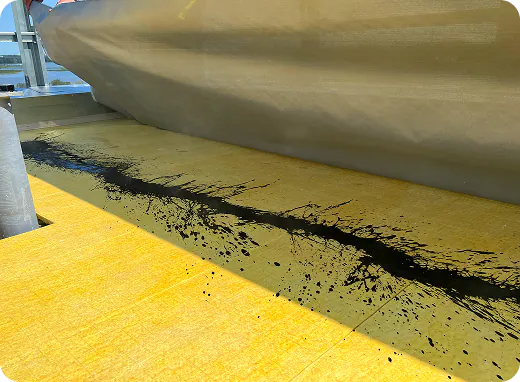

Why Most Roofs Can’t Be Tested

Most waterproofing membranes are installed over non-conductive surfaces like thermal insulation, cover boards, or even the supporting deck. Without a conductive substrate, Preventive Testing with ELD doesn’t work — making early-stage testing, post-trade inspections, and repeatable long-term verification impossible.